Sling Protection

The #1 Cause Of Synthetic Sling Failure Is Cutting

Cut Protection Products are designed to improve workplace safety. Lift-All® offers a family of sling protection to protect both sling and load from damage. Our cut protection products like Sling Shield™ and Edge Defender™ are ideal edge protectors that improve workplace safety.

Wear protection products serve to extend sling life by reducing abrasive wear and prevent marring of the load surfaces. Increase sling life with Lift-All wear pads. Choose the material that best suits your lifting needs. Contact our team of experts to find the best sling protection method.

Edge Defender

Edge DefenderThe Edge Defender product line is patented technology. Constructed with multiple layers of protection material with Kevlar® aramid binding, the Edge Defender has become the new standard in edge cut protection technology for guarding synthetic slings. Protect your loads and your slings now by using the Lift-All Edge Defender!

- Cut Protection: The patented technology creates a high level of compression on the surface to produce a superior level of cut protection.

- Conforms to the Shape of Load Edges: The flat design will conform to the load shape during handling operations, yet the construction is firm enough to prevent wrinkling.

- Ease of Attachment: The use of hook and loop straps allow quick attachment and helps to hold position on slings.

Edge Defender Flex Plus

Edge Defender Flex PlusEdge Defender Flex Plus is made of Dyneema® fiber which is woven to provide cut protection for a variety of edges and surfaces. The ‘Flex Plus’ is the addition of a double-plied layer of Dyneema with Kevlar® aramid binding. These pads are thinner, lighter, and more flexible than the standard Lift-All Edge Defender, yet maintain the same level of cut protection performance. The Edge Defender Flex Plus is well suited for handling loads with a straight, curved or non-uniform shaped edge, including coil handling applications.

Flat & Tubular Style Cut Protection

- 360° of Protection: The Edge Defender Flex Plus tubular style pad is well-suited for use with roundslings and affords uniform cut protection around the exterior of the sling body.

- Pad Positioning: When sized properly, this tubular pad will offer protection in the desired location on slings.

- Lighter and More Flexible: The patented Edge Defender Flex Plus technology creates a high level of compression on the interior surface to produce a superior level of cut protection.

- The flat Edge Defender is almost twice as flexible and maintains the same high level cut protection performance as the standard Edge Defender.

Sling Shield

Sling ShieldStop replacing your synthetic slings and wear pads due to cutting; use Lift-All Sling Shields.

Sling Shields are constructed with a low-weight, high-strength aluminum center bar and offer the highest level of cut protection of our standard products. They provide a 1” bend radius to protect your slings from even the sharpest load edges and sustain sling tensions of up to 25,000 pounds per inch of sling contact width. Velcro® strips hold sling in place and a magnetic surface retains position on the steel load. Sling Shields are well suited for loads having a straight contact edge, such as I-Beams.

- Magnetic: Holds position against steel loads for ease of rigging.

- 1″ Bend Radius: The design provides a bend radius to reduce bearing pressures for synthetic slings.

- Ease of Sling Inspection: The open design allows easy access to slings during their frequent inspections.

- Cut Protection: Sling Shields provide a very high level of cut protection, supporting sling tensions of up to 25,000 pounds per inch of contact width.

Wear Protection

- Sling and Load Damage Protection: Wear Protection can help to protect both the sling and the load from wear damage.

- Construction Materials: A variety of padding materials are available to best suit the needs of each application.

- Ease of Sling Inspection: Length selection and other pad options are available that allow easy access to slings for frequent inspections.

- Ease of Attachment: Some styles use hook and loop fastening to allow quick attachment and to help keep the position on the sling.

SLEEVE TYPE

Preferred for slings that are used in a variety of lifting situations. Easily repositioned along sling body to accommodate loads of various sizes. Sleeve allows sling to adjust to lift without movement against load edge.Tubular Quick Sleeve Use with: Tuflex® Roundslings, Chain & Wire Rope

Available Materials: All (except PVC)High strength hook & loop sleeve for secure positioning. Tubular design gives maximum usable surface and maximum pad life. Flat Quick Sleeve Use with: All Slings

Available Materials: All (except PVC)Hook & loop sleeve allow easy installation and removal. Friction keeps sleeve in place when rigging Flat Sewn Sleeve Use with: All Slings

Available Materials: All (except PVC)Preferred for long-term use on single sling. May be repositioned as needed along sling length. May require factory installation for slings with hardware and single leg Tuflex. Poly Pads Use with: Web Slings

Available Materials: PVCSlides easily along sling length for convenient sling protection. Must be installed at factory for web slings with hardware. SEWN-ON TYPE

For use on web slings where repetitive lifting situations expose the sling to damage. Eliminates the need to position pad before each lift.Sewn-On Wear Pad Use with: Web slings only

Available Materials: All except ballistic nylonFor sling protection at expected wear points. Can be sewn anywhere on the sling, be any length and be on one or both sides. Edge Guard Use with: Web slings only

Available Materials: Texture nylon, Light leatherHelps protect both edges of the sling. Placement on the sling per customer is required. Wear Pad Materials

Pukka-Pads (P) 0.3125″ Thick

A high-density polyester felt.

Webmaster® 1600 (D/N) 0.1875” Thick

Polyester (D) or Nylon (N).

Heavy Leather (HL) 0.15625” Thick

Genuine top-grain cowhide. May require multiple pieces.

PVC Belting (PVC) 0.125″ Thick

Non-absorbent conveyor-type belting.

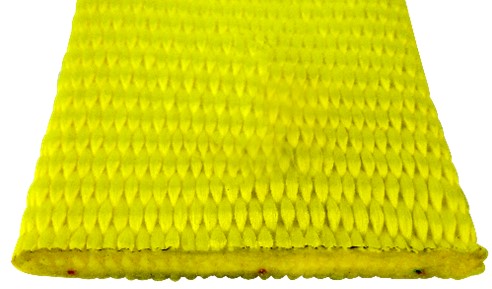

Texturized Buffer (TN) 0.09375” Thick

A bulked fiber is used to produce a thin webbing with good abrasion resistance.

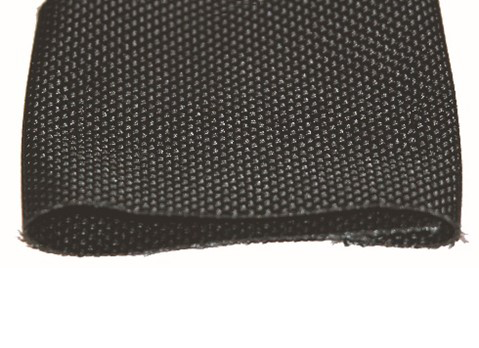

Ballistic Nylon (BN) 0.0625” Thick

A 2-ply wear-resistant fabric made of bulked nylon fiber, appropriate for wider sleeves.