Wire Rope Slings

Least Expensive Per Capacity Of All Steel Slings

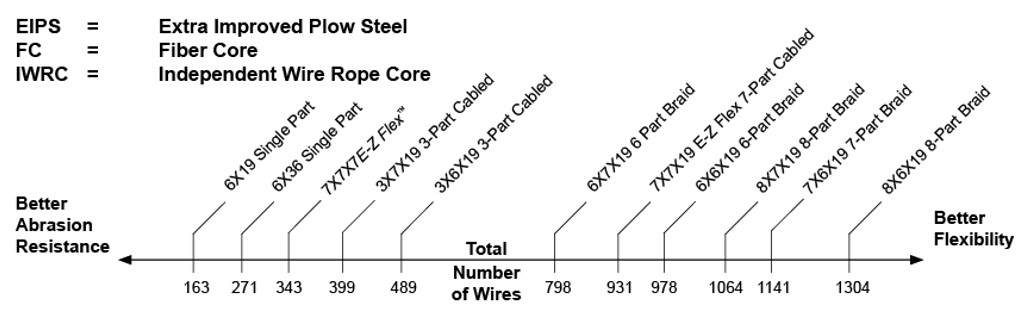

Lift-All wire rope slings are both flexible and resistant to abrasion. These characteristics are determined by the rope construction. Fewer wires result in larger diameter wires, better abrasion resistance, and reduced flexibility. More wires result in decreased wire diameter, reduced abrasion resistance, increased flexibility, and kink resistance. Wire rope products may be proof-tested upon request. If they contain swaged terminations and will be used as a sling, they will be 100% proof tested.

Numerous body constructions, such as bridle slings, endless slings, and eye-and-eye slings, allow for use in a variety of applications. Lift-All wire rope slings are made using the Flemish Eye Splice technique. Unlike the simple return loop method, which places 100% of its strength on the swaged sleeve, wire rope slings have reserve strength should the sleeve become damaged in use.

Wire Rope Slings

Wire Rope SlingsLift-All® wire rope slings are made using the Flemish Eye splice technique to form the eyes. Unlike the simple return loop method that places 100% of its strength on the swaged sleeve, wire rope slings have reserve strength should the sleeve become damaged in use.

- Reserve strength: Integrity of eyes not solely dependent upon steel sleeves.

- When specified, thimble eyes protect wire rope from wear for increased life.

- Good abrasion resistance for longer life.

Bridle Wire Rope Slings

- Bridles provide better load control and balance.

- Independent wire rope core resists crushing.

- Alloy steel hardware assures long life.

- Thimble eyes protect wire rope from wear for increased life.

- Reduces load damage by using fixed points on load.

- Easier rigging provided when hooking into fixed lifting points.

Endless Wire Rope Slings

Made from one 6X19 or 6X37 EIPS IWRC wire rope, mechanically joined with steel sleeves. Achieves higher capacities at a lower cost.

- Load stability and balance can be achieved by spreading sling legs in a basket or choker hitch.

- Wear points can be shifted to extend sling life.

- The most versatile style of sling – fewer slings to inventory.

- More flexible than eye slings of comparable strength.

- Ideal for turning loads.

Eye/Eye Style Slings

- Reserve strength: Integrity of eyes not solely dependent upon steel sleeves.

- When specified, thimble eyes protect wire rope from wear for increased life.

- Good abrasion resistance for longer life.

Wire Rope Class 6X19 EIPS IWRC 6X37 EIPS IWRC Rope Dia. (in.) 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2 1-3/4 EIPS

IWRC

Rated

Capacity*

(tons)Vertical 0.65 1.0 1.4 1.9 2.5 3.2 3.9 5.6 7.6 9.8 12 15 18 21 28 Choker 0.48 0.74 1.1 1.4 1.9 2.4 2.9 4.1 5.6 7.2 9.1 11 13 16 21 Vertical

Basket1.3 2.0 2.9 3.9 5.1 6.4 7.8 11 15 20 24 30 36 42 57 * Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

Rope Dia (in.) Rated Capacity* (tons) Vertical Choker Vertical Basket 7x7x7 1/4 0.50 0.34 1.0 3/8 1.1 0.74 2.2 1/2 1.9 1.3 3.7 5/8 2.8 1.9 5.5 7x7x19 3/4 4.1 2.8 8.1 7/8 5.4 3.7 11 1 6.9 4.7 14 1-1/8 8.3 5.8 17 1-1/4 9.9 7.0 20 1-1/2 13 9.1 26 * Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

E-Z Flex Wire Rope Slings

E-Z Flex Wire Rope SlingsE-Z Flex slings are made from a machine laid rope that consists of seven individual, galvanized ropes.

Eye/Eye E-Z Flex Wire Rope Slings

- Galvanized coating for corrosion resistance and longer life.

- 8 standard eye combinations.

- Available in 7x7x7 and 7x7x19

Bridle E-Z Flex Wire Rope Slings

- Bridles provide better load control and balance.

- Sliding choker hook speeds rigging of bundled materials.

- Alloy steel hardware assures long life.

- Easier rigging when hooking into fixed lifting points.

- Sliding choker hook speeds rigging of bundled materials.

Endless E-Z Flex Wire Rope Slings

- Load stability and balance achieved by spreading sling legs in basket and choker hitches.

- Wear points can be shifted to extend sling life.

- Smaller rope diameter per capacity increases flexibility.

- Ideal for turning loads.

- More flexible than eye slings of comparable strength.

Black Wire Rope Slings

Black Wire Rope SlingsAn ideal solution for the Entertainment Industry

- Standard sizes available from 18″ to 50’.

- Designed for entertainment stage rigging.

- Heat resistant for your most demanding suspension applications

- Black color conceals sling in the ceiling better than silver wire rope.

- A grey capacity tag with black lettering aids in the camouflage of the sling.

- Heavy duty thimble / thimble configuration protects rope eyes from wear for increased life.

- Available in 1/2” 6×19 black imported galvanized IWRC and 3/8” 7×19 black import GAC.